Meet SPARTAN

SPARTAN is the world’s first entirely 3D-printed scramjet engine, delivering performance, reliability, lead time and cost advantages over more bespoke manufacturing methods.

Air-breathing engine

The simple, robust and reusable air-breathing engine system is the result of 30 years’ research, more than 6,000 ground firings, and 11 sub-orbital flights through the HIFiRE and HyShot programs.

3D printed high temperature alloys

Hypersonix 3D printed the world’s first fixed geometry scramjet engine in 2021. The maximum speed that can be achieved is depending on materials used.

Reusable and fuel-efficient

Our reusable, self-igniting SPARTAN has no moving parts and uses green hydrogen fuel to minimise environmental impact as it has no CO2 emissions.

Water vapour exhaust

Unlike other launch systems on the market, the SPARTAN scramjet produces only H2O exhaust and can leverage the sustainable benefits of green hydrogen fuel.

Ceramic Matrix Composites (CMC)

SPARTAN is made from CMCs as they are lightweight, with a high strength-to-weight ratio (even at high temperatures), high thermal shock resistance and toughness.

Powered by hydrogen

Hypersonix’s SPARTAN scramjet uses hydrogen as fuel for its high thrust and longer flight times.

Specifications

Better, greener scramjet technology

Several environmental studies indicate rocket emissions impact our stratosphere in a way no other industrial activity does. This reality is the current cost of sending payloads into orbit through chemical propulsion.

Hypersonix believes in creating technology for a cleaner, more sustainable Earth.

SPARTAN’s combination of green hydrogen fuel — using solar power to generate H2 from seawater — and fully reusable design is an innovative scramjet technology approach, in an industry that otherwise wastes materials and energy.

Hydrogen is fuel for a low carbon future

Hydrogen can be produced from just water, using renewable energy. Burning it in an engine produces only water vapour. There is a global movement towards low-carbon fuels and Australia is set to become a key player in the hydrogen industry, with government and private investment into local green hydrogen production facilities.

Hypersonix has partnered with BOC Australia, who has announced its intention to build a green hydrogen production facility using seawater as the main ingredient, in Queensland.

The clean hydrogen industry is growing quickly Australia-wide, with over $1.6 billion invested in the private sector and $1.27 billion in the public sector. The price of clean hydrogen is projected to decrease to between $2 and $4 per kilogram by 2030.

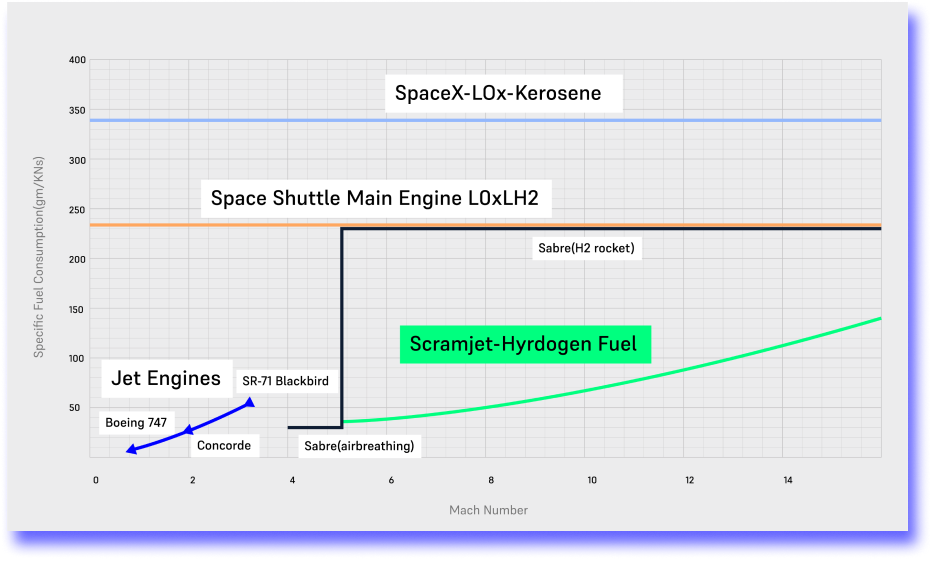

Hydrogen is an excellent aerospace fuel

The space industry has historically utilised hydrogen as rocket fuel, including in the space shuttle program.

Hydrogen is non-toxic and its low density means any leaks and fires are directed upwards — unlike hydrocarbon fuels, which could pool under the aircraft. Hypersonix’s vehicles are also unmanned, reducing the risks to humans. Hydrogen has approximately 2.5 times the energy density of hydrocarbon fuels, such as kerosene, making it the perfect fuel in an industry where every gram counts.

Get in touch with us

To discuss our scramjet engines, flight systems or launch systems with a Hypersonix representative, please complete the contact form.

Contact us